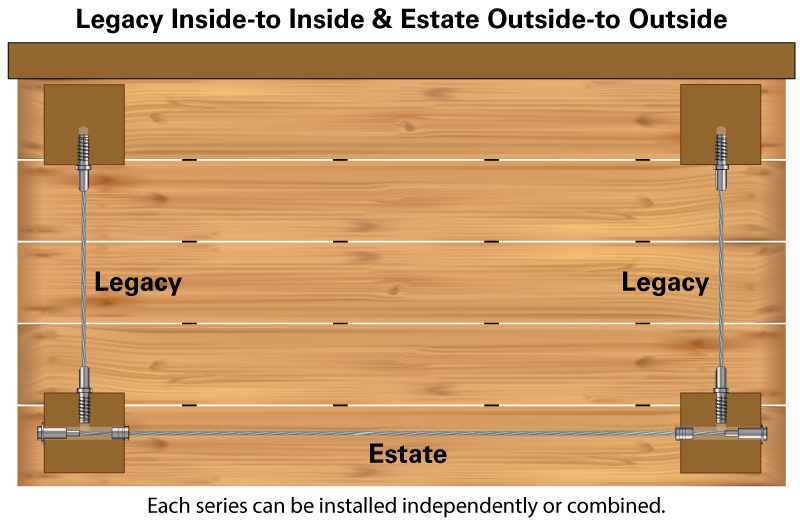

Cable Rail Hardware Needed

Installing a wire cable railing system is

best performed as a two-person project

to ensure accuracy, safety, and ease of handling throughout the process.

WiseRail

®

CableRail

®

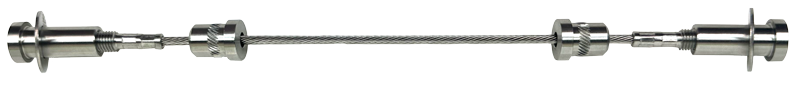

American Made cable rail hardware

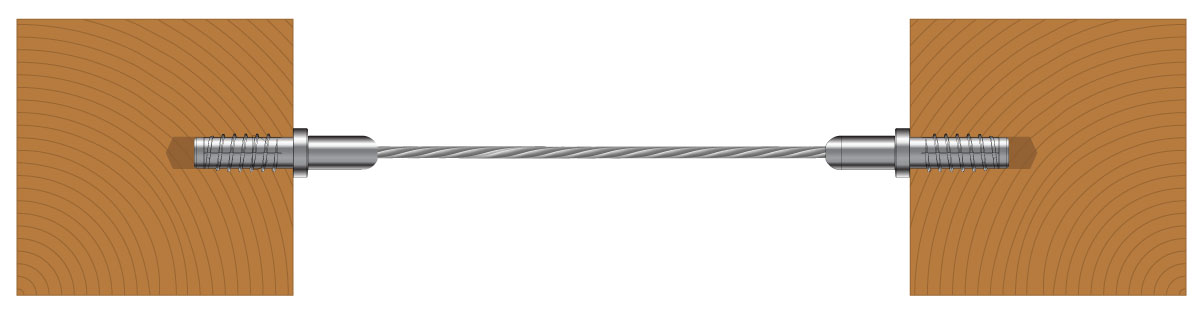

fittings are specifically designed for level-run installations using

4"x4" or 6"x6" wood posts

(minimum actual dimension of 3½" square). Each hardware pack contains the necessary components for runs of

1/8" stainless-steel cable

. To complete your project, be sure to purchase the appropriate number of infill pack for your desired railing height:

-

36" railing height: 10 infill packs required

-

39" railing height: 11 infill packs required

-

42" railing height: 12 infill packs required

All hardware is manufactured in the USA at the DeckWise facility

from 316L marine-grade stainless steel, providing exceptional resistance to rust, corrosion, and extreme weather, ideal for both interior and exterior applications, including coastal environments.

Planning & Materials

Before purchasing, take time to measure your layout, estimate materials, and

plan for the number of runs, post placements, and cable lengths.

It's always a good idea to order extra materials to account for cutting errors or on-site adjustments, especially wire cable rolls and swage terminals, which may be consumed during installation or due to mistakes.

If you need assistance with estimating materials or planning your layout, our support team is available to help at

941-896-9851

.

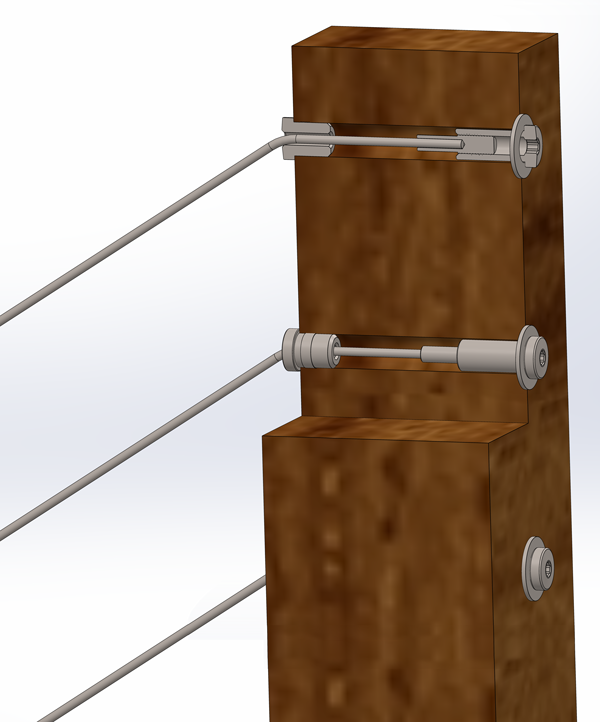

Wood Post Requirements

For most

deck rail wood post

systems, a minimum post size of 4x4 (3-½" actual) is required to withstand the tension applied by the wire cables. All terminating posts must be securely mounted to the structure to prevent loosening over time. A

top rail

is required, and we strongly recommend reinforcing it vertically beneath the top rail for additional support. A

bottom rail

is optional but may help distribute tension and reduce stress on the lower portion of the wood post assembly.

Post Hole Placement

Measure 3-1/8" down from the bottom of the top handrail to mark the top-hole location. This location will be used as a reference point for the next hole - and that hole, will be a reference for the following one, and so forth. Each hole center mark must be 3-1/8" below the last.

To define the center of the post, use the supplied hole template. Or measure the width and divide by 1/2. Example: Wood post actual width is 3-1/2” wide, divided by 1/2, equals 1-3/4” inward marks the center of the post. Mark the center of the post. Do this on opposing sides of the post to accurately align holes for tensioner installation.

Optionally apply a strip of painter’s tape vertically down the center of the wood post for marking. It will also protect the wood post finish and avoid wood blowout when drilling.

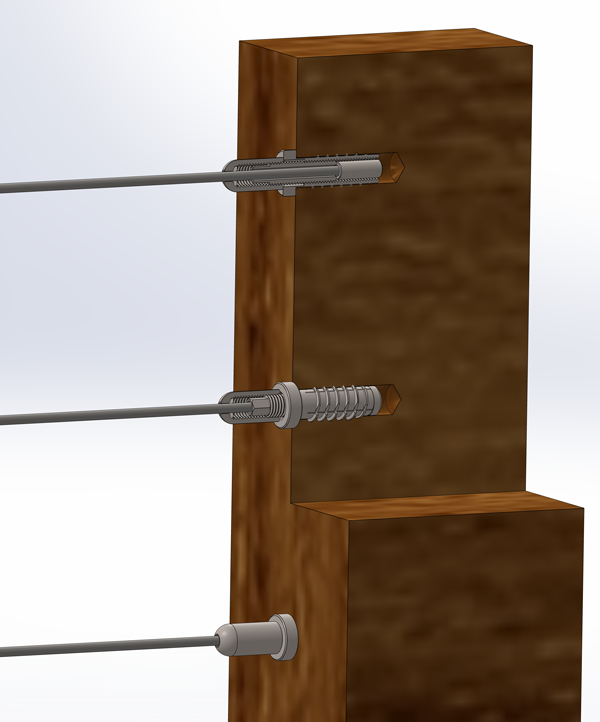

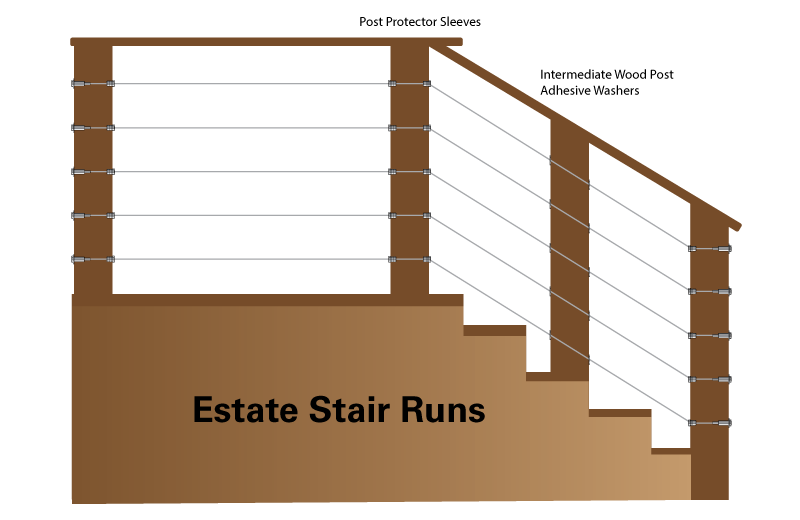

Intermediate Posts

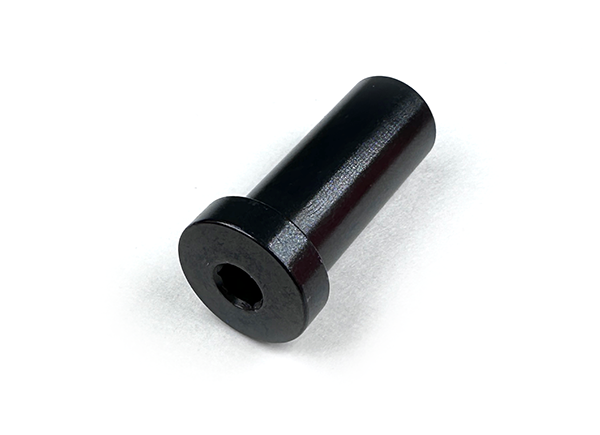

For wood intermediate posts, you must install a Post Protector Insert Sleeve (sold separately) on each side where the cable passes through.

For intermediate metal posts (square tube or flat bar), predrilled holes will typically be provided to allow cable pass-through, eliminating the need for sleeves.

Metal intermediate cable braces are inserted between posts and feature pre-drilled holes for cable pass-through. Typical options include:

-

5/8" x 5/8" aluminum square tube, or

-

1/4" thick by 1" wide stainless steel flat bar

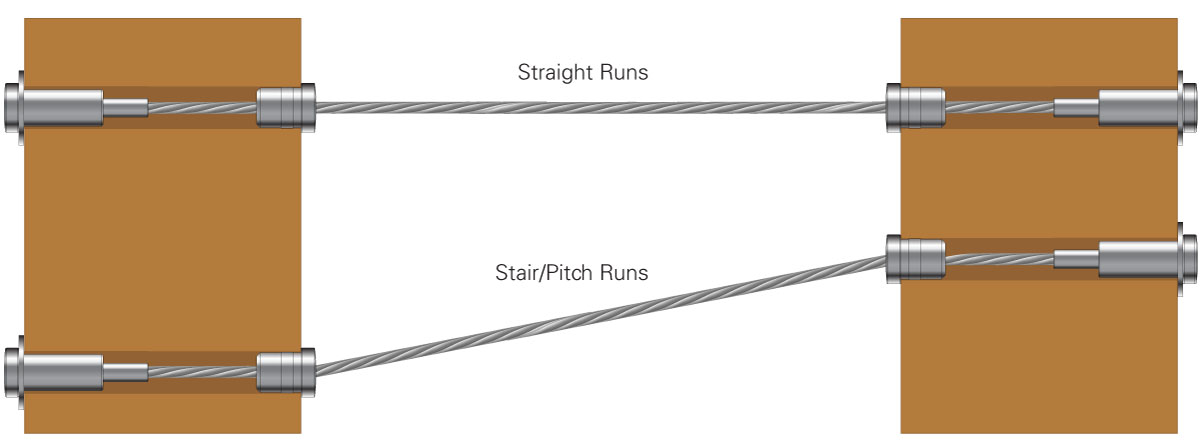

Cable Wire Spacing

To maintain both structural integrity and code compliance, it is recommended that cables are spaced with no more than a 3-inch clear span between each row. For instance, when using 1/8-inch diameter cable, drill the holes at 3-1/8 inches on center to ensure consistent spacing while accounting for the cable's thickness.

In order to prevent deflection that could violate building codes, particularly the 4-inch sphere rule, cables must be supported along their lateral run. Support spacing should not exceed 48 inches (4 feet) between supports. Intermediate posts serve this purpose, but when minimizing the number of full-size posts, supplemental cable braces may be used.

These cable braces are inserted between posts and feature pre-drilled holes for cable pass-through. Typical options include:

-

5/8" x 5/8" aluminum square tube, or

-

1/4" thick by 1" wide stainless steel flat bar

Cable braces are sold separately and offer an effective solution to maintain cable alignment and prevent sagging without adding unnecessary bulk to the railing structure.

Note:

In accordance with standard building codes, the space between the handrail and the top cable, between each cable, and between the bottom cable and the floor must be less than 4 inches at all times.

Code Compliance & Safety

Before beginning your installation, check all local building codes, including city, county, and state regulations. Railing height and cable spacing requirements vary by jurisdiction. While we design our products to meet the most common standards, we cannot guarantee compliance with every regional code, so it is important to confirm with your local building authority.

General guidelines for handrail height:

-

Level runs: Typically, 36", 39", or 42"

-

Stair runs: Generally, between 34" and 38"

Additionally, most codes require that no space within the railing system allow the passage of a 4" sphere, which governs vertical cable spacing and top/bottom clearance.

Important Safety Notice:

This cable railing system is not designed or intended to act as a containment barrier for pets, children, or any individuals who may attempt to climb, pass through, or otherwise access unsafe areas. It is solely intended as a guardrail system for fall protection and general use in accordance with applicable building codes.

Wood Installation Block

To avoid damaging the finish on Post Protector Sleeves during installation, a custom wood block should be used to help seat the sleeves securely into their holes. For best results, use a durable hardwood species when making the block.

Begin by cutting a thin wood block approximately 2 inches wide by 4 inches long and about 1 inch thick. On one of the 2-inch ends, cut a 3/16” groove to accommodate the cable wire. Then, on one of the 4-inch sides, cut another 3/16” groove. These grooves should intersect at the corner of the block to allow for both straight and angled cable insertion.

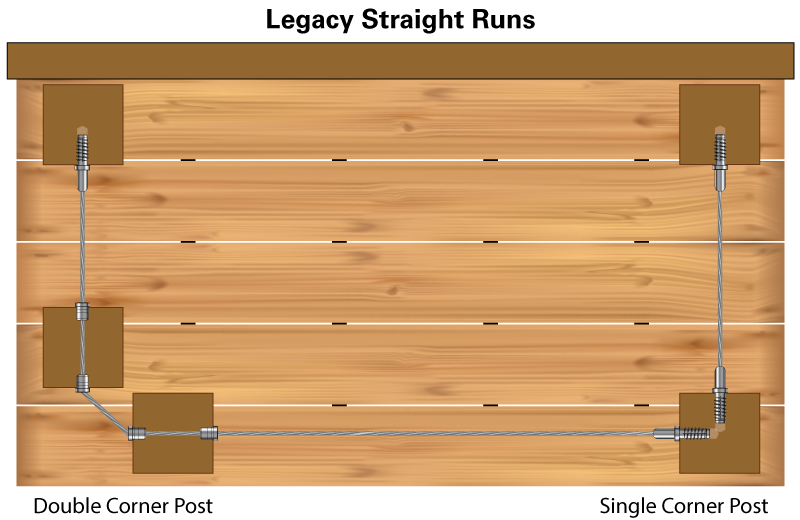

Legacy Straight/Level Runs:

Insert the cable through the groove on the 4-inch side of the block. Align the end-grain of the block with the face of the Post Protector Sleeve, keeping them flush. Using a mallet, gently but firmly strike the block to seat the sleeve fully into the hole.

Estate Stair, Angle, & Pitch Runs:

Use the corner where the 2-inch and 4-inch grooves intersect. Insert the angled cable into this corner groove, aligning the end-grain of the block with the sleeve face. Tap with a mallet to fully insert the Post Protector Sleeve without deforming or damaging the metal finish.

Optional Straight/Level Runs:

Insert the cable through the groove on the 4-inch side of the block. Align the end-grain of the block with the face of the Post Protector Sleeve, again keeping them flush. Using a mallet, gently but firmly strike the block to seat the sleeve fully into the hole.

This custom block tool helps ensure a clean, damage-free installation and should be reused throughout the railing installation process.