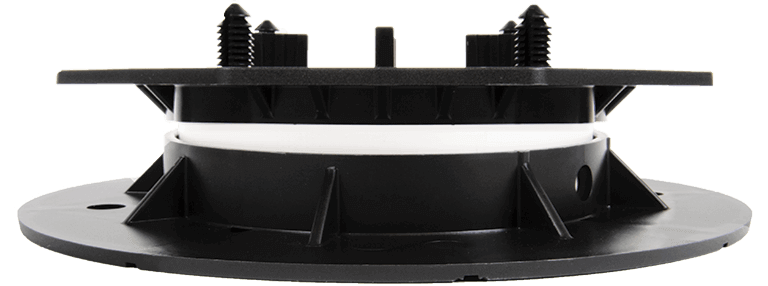

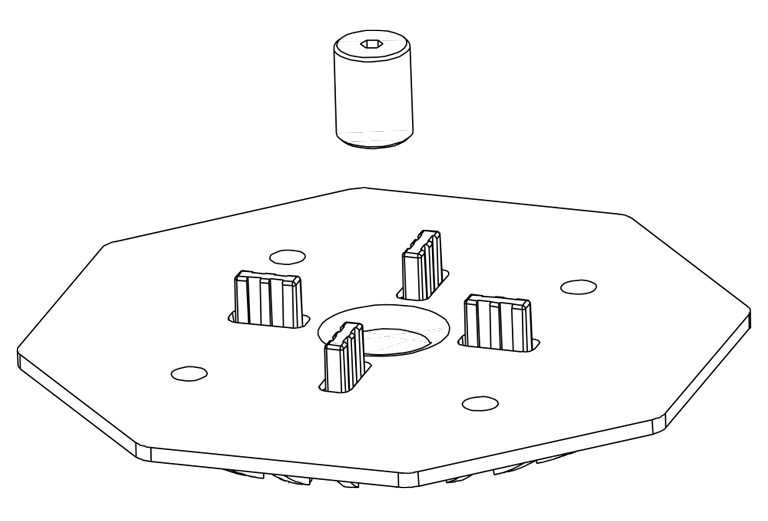

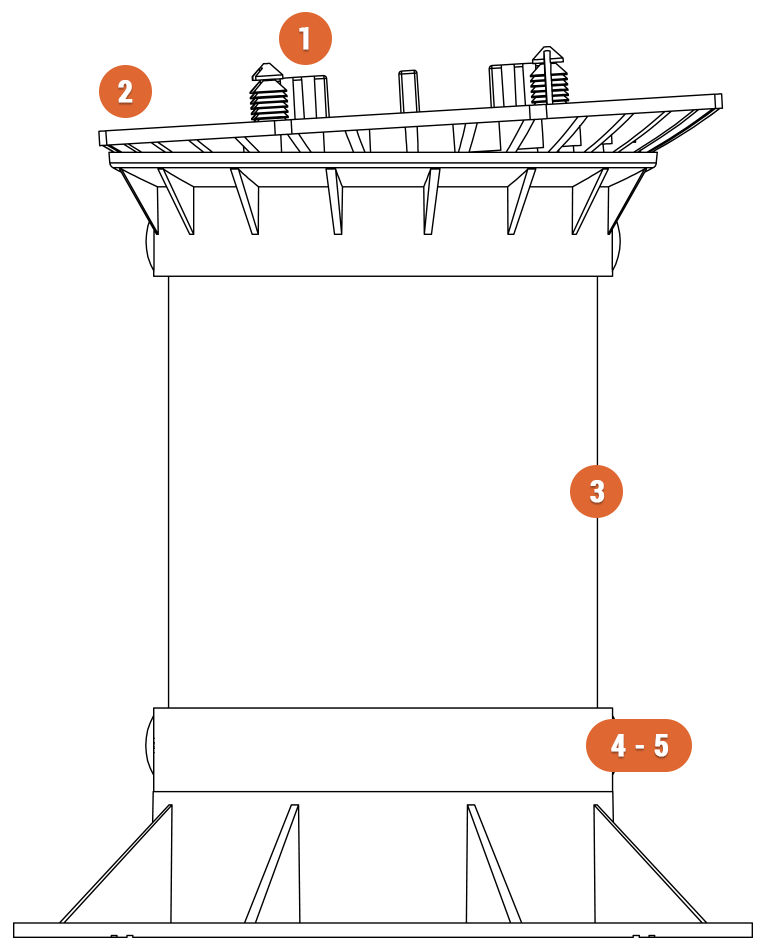

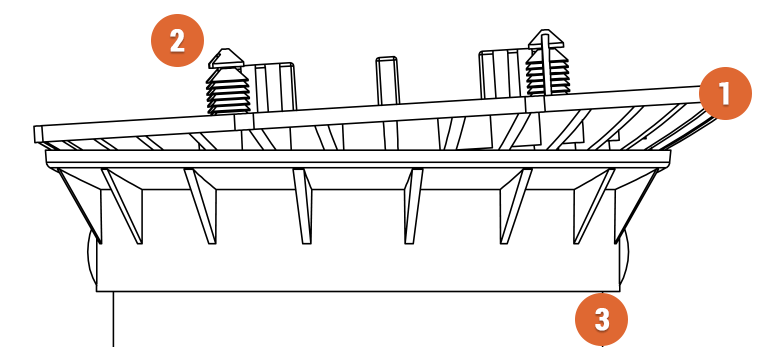

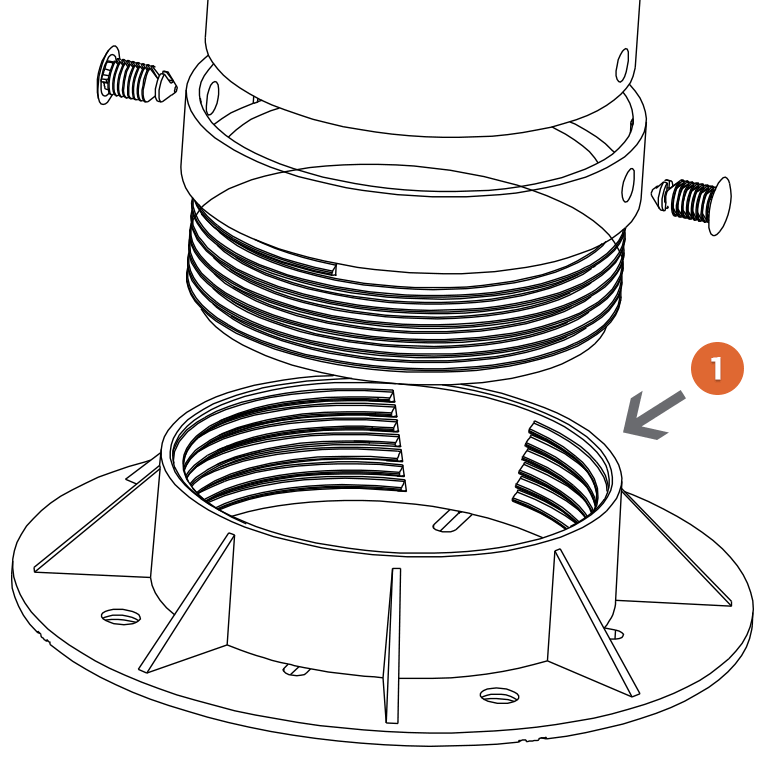

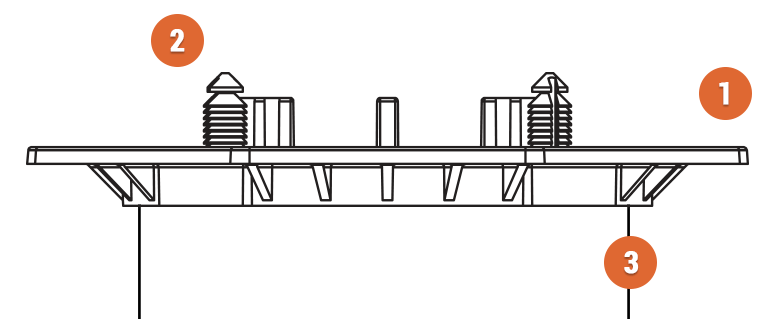

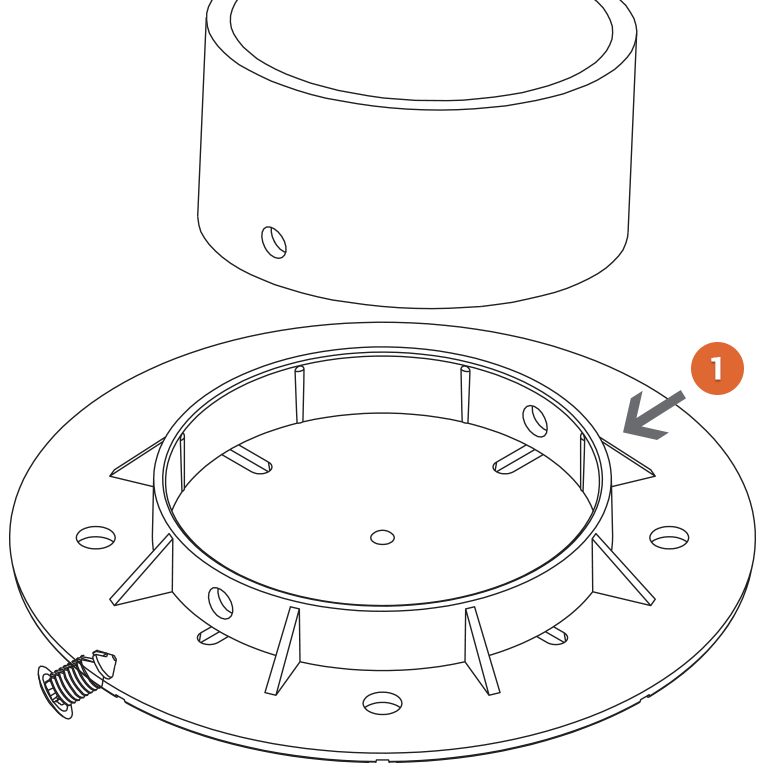

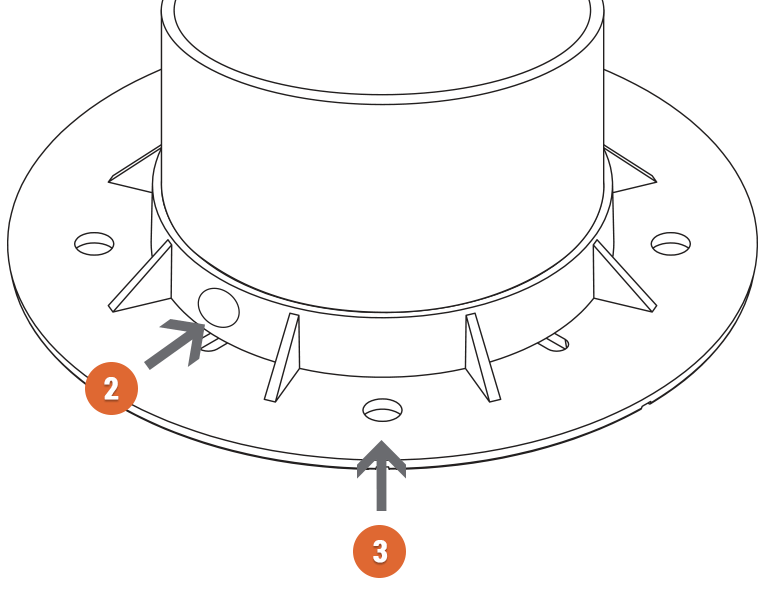

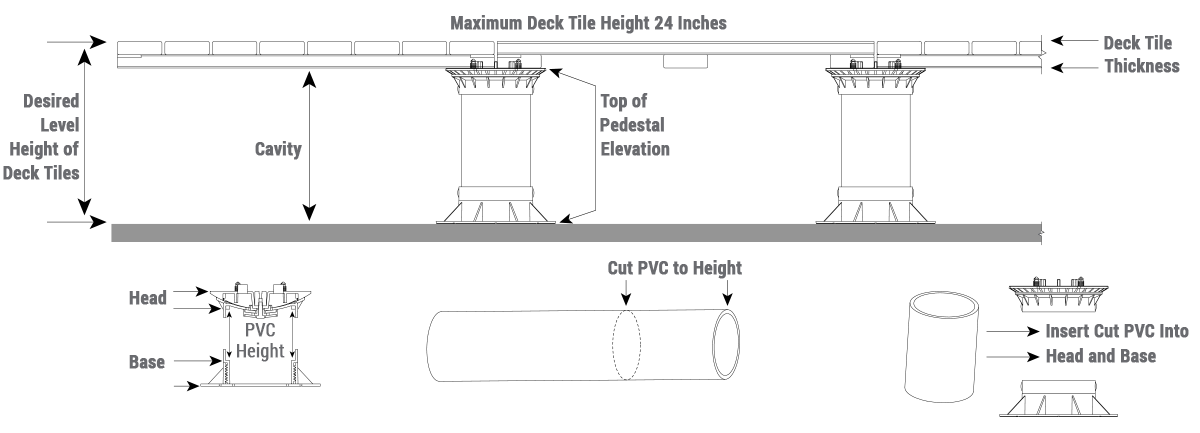

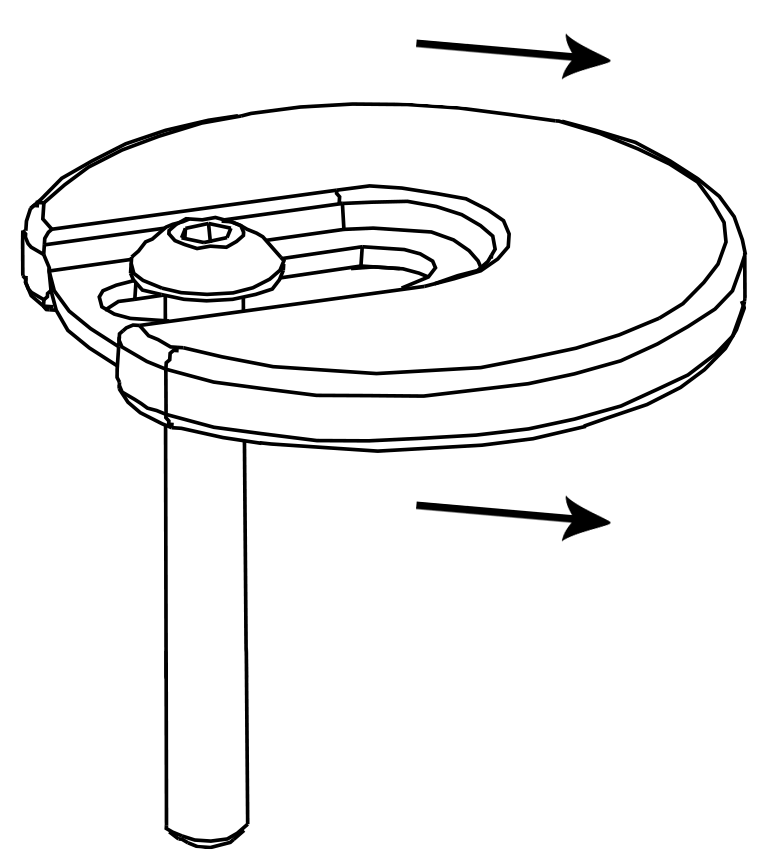

A: You would hold the PVC still/tightly and just rotate the bottom base because we suggest using the pine tree fasteners to secure the PVC to the

head and the base. If the PVC pipe were rotated while the pine tree fasteners are installed, that would rotate the head.

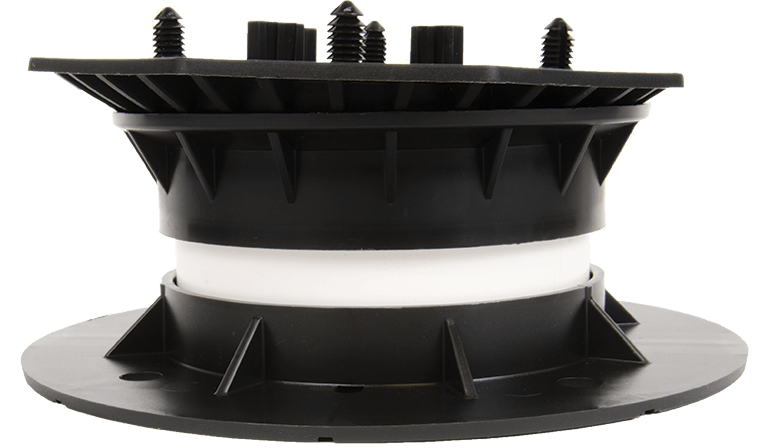

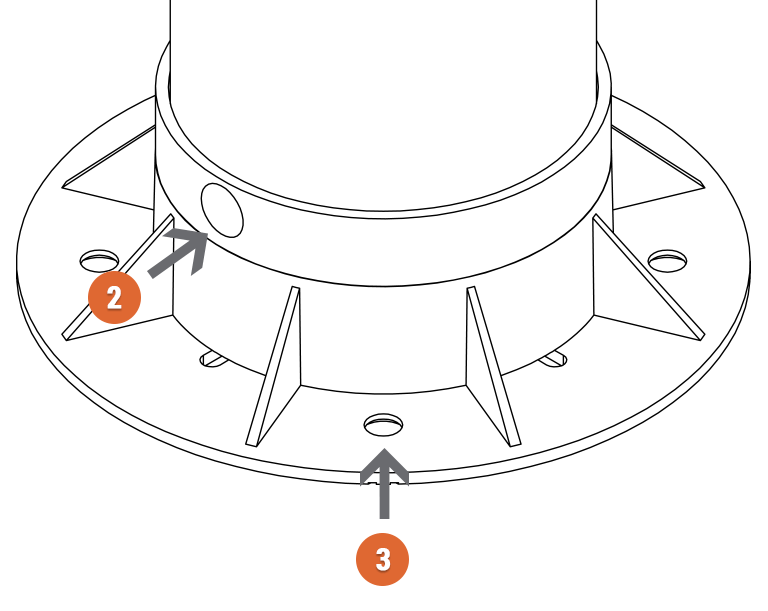

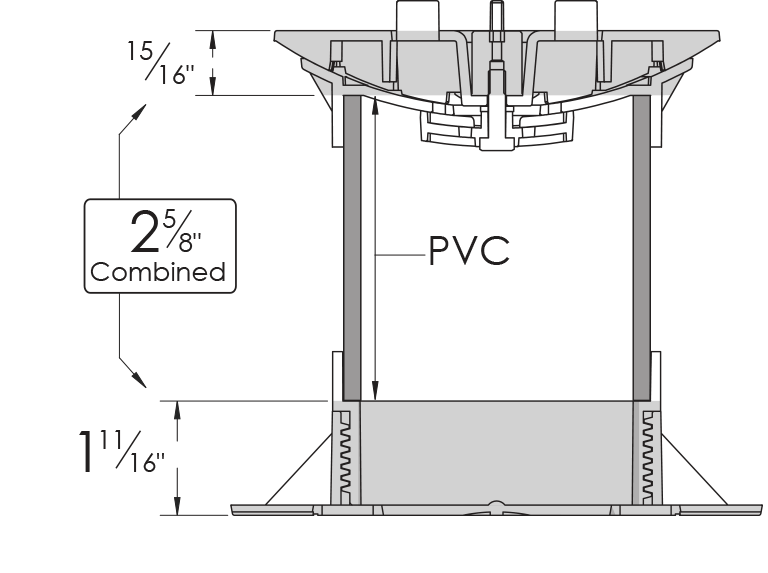

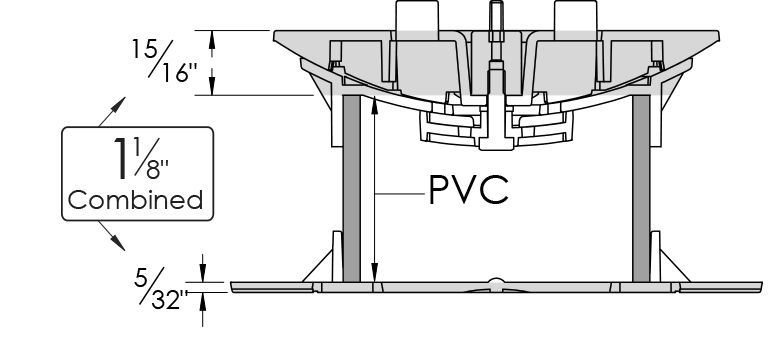

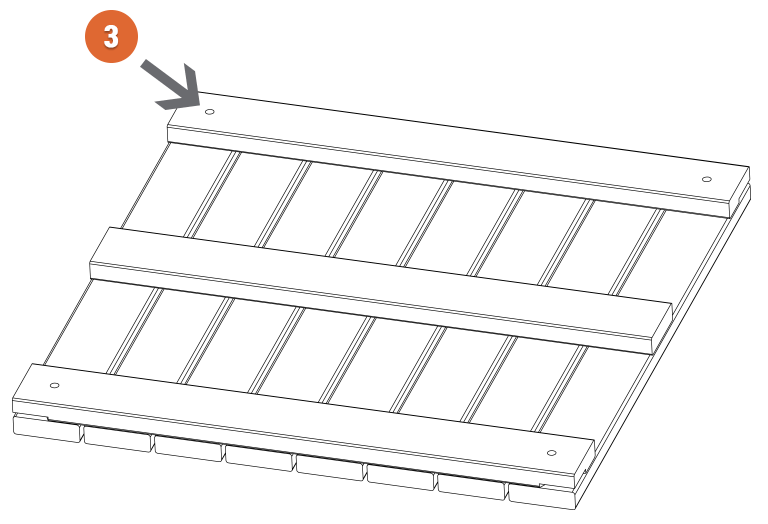

We suggest using a buffer pad under the base between the roofing membrane materials as well. This not only helps to protect the roofing membrane but

also can help with twisting the screw-jack base - if the deck tile load isn't already extremely heavy. If the load is too great to twist the base,

remove the deck wile or lift it up to release the load prior to adjusting.

An option would be to install the pine tree fasteners on the screw-jack base and PVC only – not on the head. Then the PVC pipe could be twisted which

would only turn the screw-jack base.